"Space Manufacturing" is about to debut in Asia, 3D printing is an important process

2019-02-22

3D printing is one of the important processes in space manufacturing, which can promote the ground application of related technical achievements, including aviation, deep sea, chemical, energy, medical and many other fields.

Ceramic material 3D printing

In addition to 3D printing products of traditional ceramic materials such as silicon oxide (SiO2), aluminum oxide (Al2O3) and zirconia (ZrO2), there are newly developed aluminum nitride (AlN), nickel oxide (NiO), silicon nitride ( 3D printing products of Si3N4) matrix composites and ceramic gradient functional composites (NiO-ZrO2). There are also ceramic members formed by stereolithography under microgravity and 3D printed moon soil structural members.

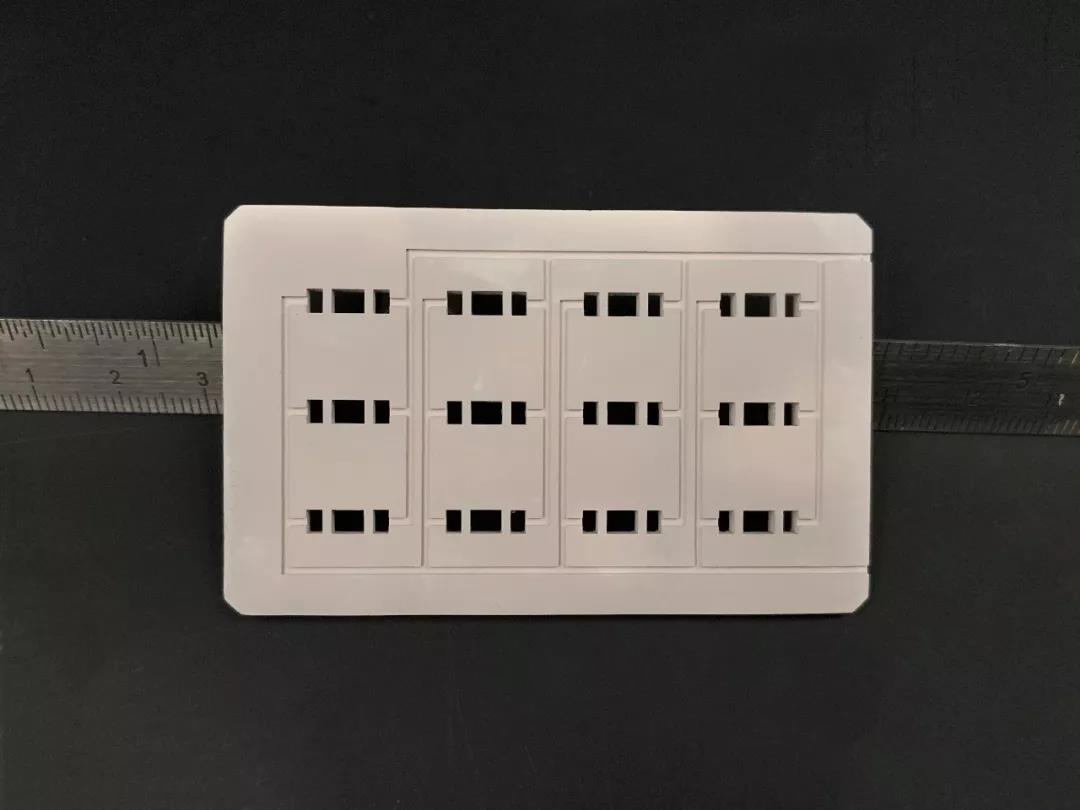

Aluminum nitride substrate

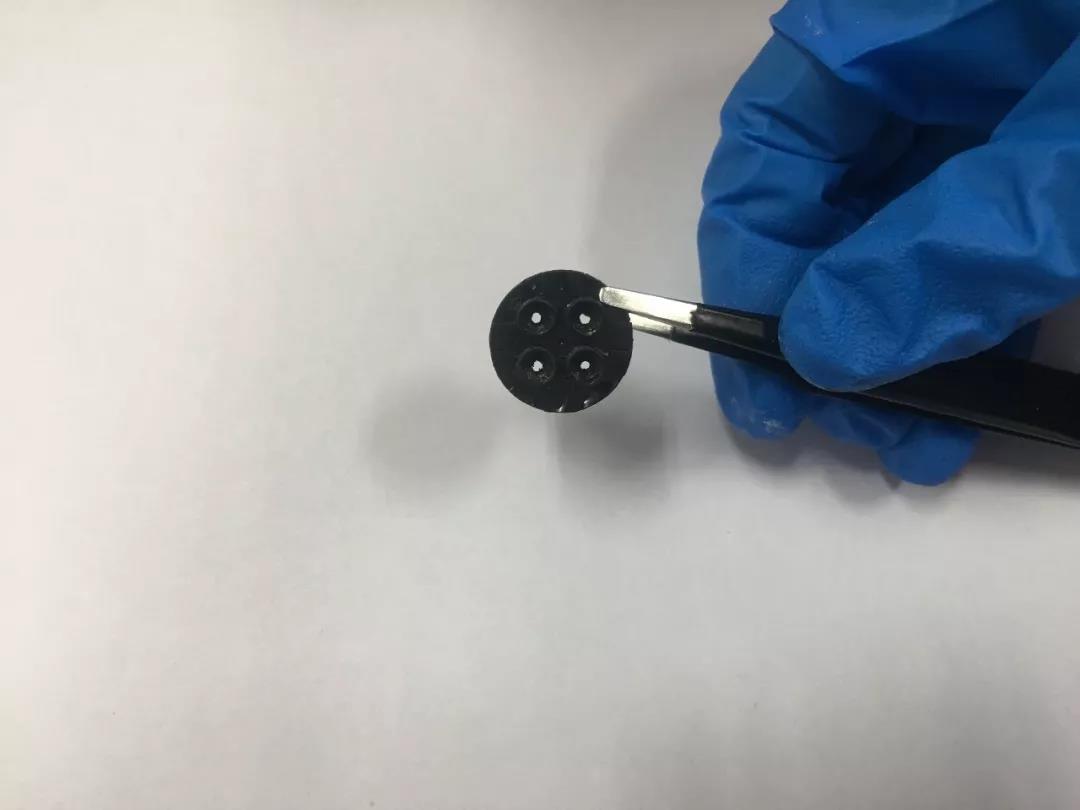

Nickel oxide chemical catalyst carrier

The catalyst carrier is a hollow cylinder and has a porous structure inside, which greatly increases the specific surface area of the carrier and improves the catalytic performance of the catalyst. This porous complex structure is difficult to manufacture by conventional means, so 3D printing is the best choice for the formation of such complex components.

Silicon nitride-based composite material - a new type of microwave-transparent heat-insulating functional integrated material

Due to its excellent dielectric properties, silicon nitride-based composites can be used as a new integrated material for microwave-transparent heat insulation. They are mainly used in the aerospace industry to protect the aircraft from normal operation under the harsh environmental conditions of communication, telemetry, guidance, and detonation. .

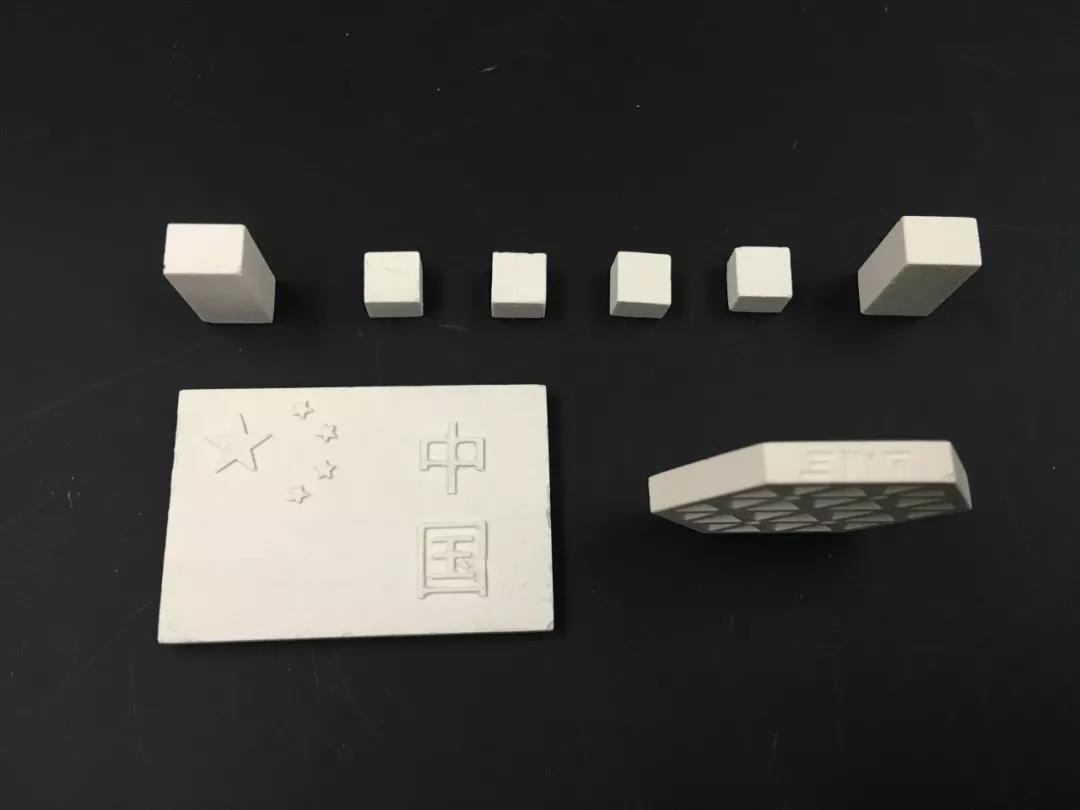

Gradient Functional Composite (FGM) 3D printing

With the rapid development of high-end technology, the functional requirements for parts and materials are also increasing. Parts made from single or homogeneous materials have become increasingly difficult to meet the performance requirements of the part. Therefore, due to its unique performance, it has attracted more and more scientists' attention. Three-dimensional printing is a technique for constructing objects by layer-by-layer printing, and is the most effective method for preparing functionally graded materials. However, the existing ceramic three-dimensional printers on the market generally can only realize the complex structure molding of a single material. CeraMatrix, a surface-exposure stereolithography 3D printer developed by researchers and space workshops, is an open-source ceramic 3D printer that can change the printing materials and adjust the printing parameters at any time during the printing process. It is the best equipment for forming functional gradient materials. Researchers have successfully implemented 3D printing of gradient functional composites of two ceramic materials (nickel oxide-zirconia) using CeraMatrix.

Gradient functional composite of nickel oxide-zirconia

The silicon-boron carbon-nitrogen ceramic component is formed by using ceramic precursor 3D printing technology, which has excellent high temperature resistance and creep resistance, and the temperature resistance can reach 1700 °C. Researchers took the lead in realizing 3D printing of organic precursor synthetic ceramic materials, filling the gap in the field in China. The research results were published in the journal Journal of the European Ceramic Society under the title "Thefabrication of SiBCN ceramic components from preceramic polymers by digital light processing (DLP) 3D printing technology".

3D printing moon soil structure

The researchers used the face-exposure stereolithography ceramic 3D printer CeraMatrix developed by independent innovation and the lunar soil 3D printing paste that meets the microgravity condition, and realized the stereolithography 3D printing moon soil material for the first time in the world, and successfully sintered without obvious Defective structural parts. The lunar soil structural member not only has high dimensional accuracy and surface finish, but also has excellent compressive strength and bending strength, and its mechanical properties are twice as high as the current international level. The research results are expected to provide the necessary technical reserves for the in-place manufacturing and extraterrestrial resources in the future space exploration in China. The research results were published in the journal "Ceramics International" under the title "Digital light processing of lunar regolith structures with highmechanical properties".